From smartphones and drones to electric vehicles, one silent powerhouse drives them all — the Lipol battery. Once a cutting-edge term in research labs, the lithium polymer battery has now become the “energy heart” of our everyday tech. Let’s take a closer look at why this compact power source stands out, and how it powers the modern world.

1. What Makes LiPol Batteries So Special?

Unlike traditional lithium-ion batteries that use liquid or gel electrolytes, LiPol batteries use a semi-solid or gel-like polymer electrolyte — and that’s a game changer.

Ultra-Slim & Flexible

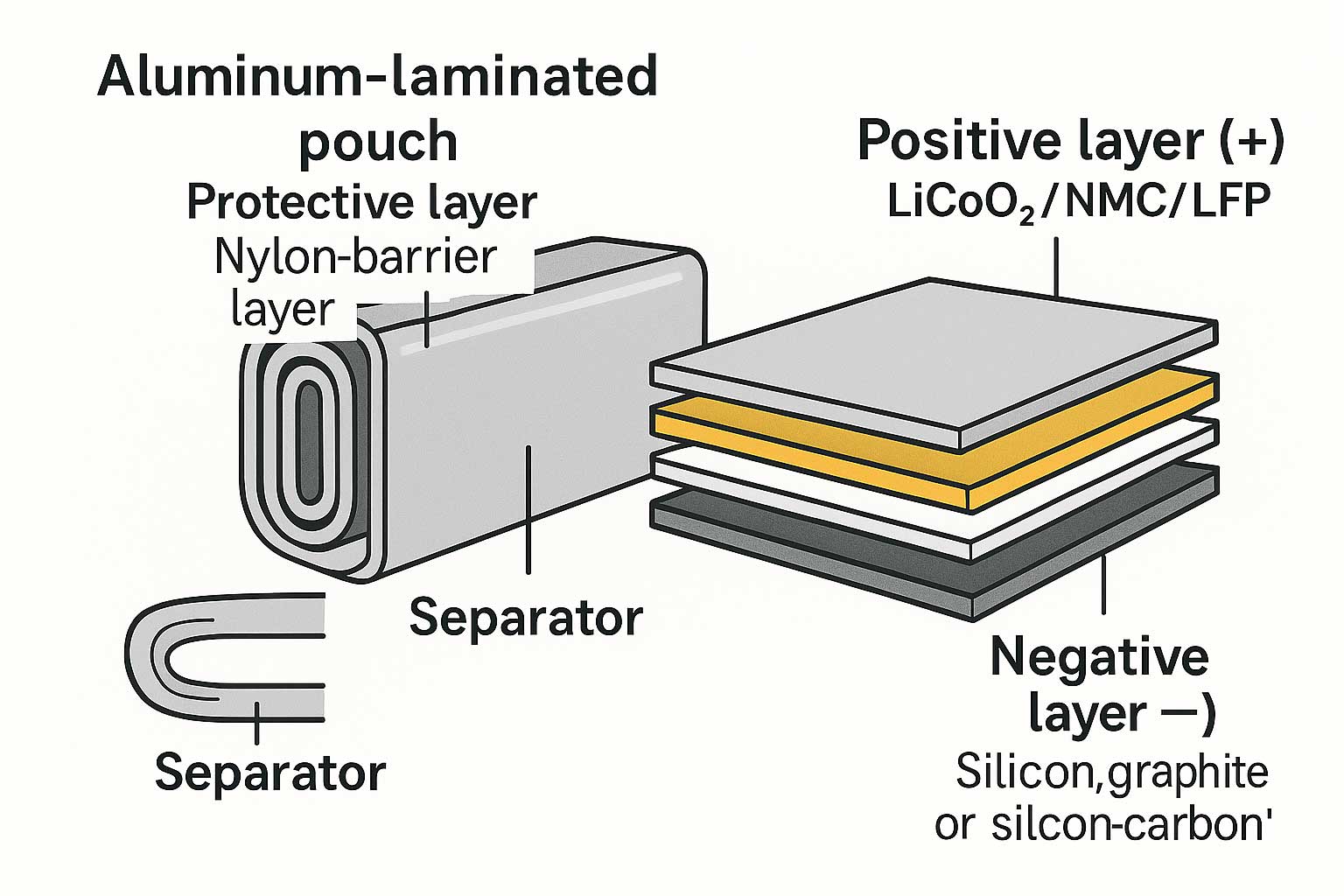

LiPol batteries ditch the bulky metal casing and instead use aluminum laminate film packaging, allowing for ultra-thin and bendable designs. That means they can be molded into flat, curved, or even irregular shapes — ideal for wearables, foldable phones, or any device with tight space constraints.

Lightweight, High Energy Density

By eliminating metal shells, LiPo cells offer more energy per gram and per cubic centimeter. Flagship smartphones with 4000mAh or more rely on LiPo to keep the weight down without sacrificing runtime.

More Power in Less Space

LiPol batteries typically deliver 150–250 Wh/kg of energy density — and experimental models even surpass 300 Wh/kg. Compared to 18650 cylindrical cells (150–220 Wh/kg), that’s a leap in performance, enabling longer use on a single charge.

Safer By Design

The gel-like or solid-state electrolyte reduces leakage risks. Even if the pouch is damaged, the contents won’t spill easily, lowering the chance of short circuits or fire. Of course, smart BMS and protection circuits are still essential.

Lower Self-Discharge

Thanks to polymer-based electrolytes, most LiPo batteries have a low self-discharge rate — typically around 2–5% per month. That means they retain power longer when not in use.

2. Where You’ll Find Them: LiPol Batteries in Action

Because they’re lightweight, powerful, and easily shaped, LiPol batteries dominate in areas where performance, size, and flexibility matter most.

Consumer Electronics

LiPo batteries are the secret behind the slim profiles and long battery life of smartphones, tablets, ultrabooks, TWS earbuds, and smartwatches.

Wearables & IoT Devices

In smart glasses, health monitors, and embedded sensors, custom-shaped LiPo batteries allow for miniaturized and irregular designs.

Drones & RC Models

With their high energy density and discharge rate, LiPo packs give drones long flight times and powerful thrust.

Portable Medical Equipment

Devices like pacemakers, monitors, and hearing aids depend on LiPo for their safe, compact, and reliable power needs.

Power Tools

Modern cordless drills and saws use high-rate Lipol battery packs for strong output without adding excess weight.

EVs & Future Mobility

While mainstream EV batteries still rely on prismatic or cylindrical formats (like LFP or NMC cells), LiPo is gaining ground in 12V low-voltage systems, hybrids, and solid-state battery prototypes, due to its flexibility and safety potential.

3. The Art of Customization: How LiPo Batteries Are Made

LiPo batteries are prized for their customizability — crucial for meeting various design demands in modern electronics. Here’s how they’re crafted:

Electrode Manufacturing

- Slurry Mixing: Active materials (like LCO, NCM, or LFP), conductive agents, binders, and solvents are blended into a uniform paste.

- Coating: The slurry is applied onto aluminum foil (cathode) or copper foil (anode) with precise thickness.

- Drying & Calendering: Electrodes are dried, then pressed with rollers to increase density and adhesion.

- Slitting: The wide electrode sheets are cut to the required widths.

Cell Shaping: Stacking vs. Winding

- Stacking: Like building a sandwich, layers of cathode, separator, and anode are stacked to form shapes such as L-shaped or polygonal cells — perfect for custom or irregular battery layouts.

- Winding: Cathode, separator, and anode are wound into a jelly-roll structure — more efficient but better suited for cylindrical shapes.

Pouch Cell Assembly (The Key Difference)

- Packaging: The electrode stack is inserted into a laminated aluminum pouch with multiple layers — nylon (outer), aluminum (middle), and polypropylene (inner seal).

- Sealing & Filling: The pouch is heat-sealed on three sides. Then a precise amount of electrolyte is injected through the fill port.

- Formation & Aging: First charging activates the battery and forms a stable SEI film. Poor cells are rejected.

- Final Sealing & Shaping: After vacuuming, the fill port is permanently sealed, and the pouch is shaped or flattened.

- Assembly & Testing: Tabs are welded, a protection circuit board (PCB) is added, and the battery undergoes full performance and safety tests — overcharge, short circuit, puncture, etc.

Every aspect — formula, shape, tab position, BMS — can be tailored. That’s what gives engineers freedom to design without limits.

4. Looking Ahead: Innovation & Challenges

Lipol battery tech is evolving fast. Here’s what’s shaping the future:

- New Materials: Silicon anodes, high-nickel cathodes, and solid electrolytes aim to boost energy and safety.

- Smarter Manufacturing: AI-based MES systems and advanced coating/stacking tools improve precision and efficiency.

- Battery Recycling: With billions of cells in use, sustainable recycling methods are becoming critical.

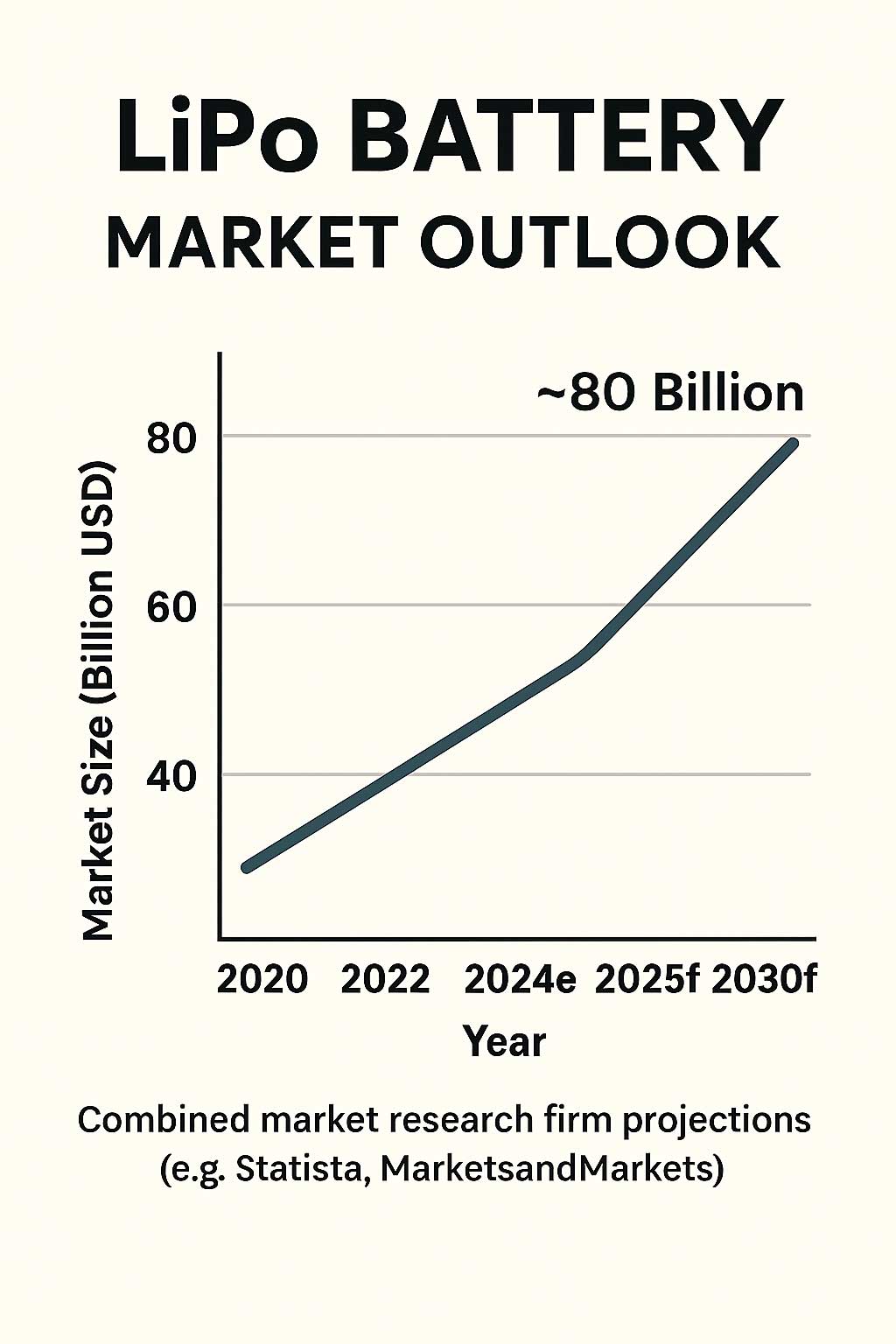

Key Industry Insights (2023–2024)

- According to Statista and MarketsandMarkets, the global Lipol battery market will exceed $80 billion by 2025, driven by consumer electronics and energy storage.

- Top battery makers — CATL, BYD, LG Energy Solution, Panasonic — are investing heavily in next-gen LiPo and solid-state R&D.

- The next energy density targets? 350–400 Wh/kg, with some labs eyeing 500 Wh/kg breakthroughs.

Final Thoughts

Lightweight, high-capacity, and endlessly adaptable, the Lipol battery is the silent force powering our pocket devices and shaping future energy solutions. Whether in your phone, drone, or smartwatch, these tiny power packs are revolutionizing the way we live, work, and move.

Next time you scroll on your phone or watch a drone hover overhead, remember the little “energy wafer” inside — small, silent, and brilliantly powerful.